The spindle is one the most crucial components in advanced manufacturing where accuracy and dependability cannot be compromised. The machining spindle is whether it is used to sculpt high-quality aerospace alloys or fine-tune components for medical devices with high tolerance, is the force that drives the precision and speed.

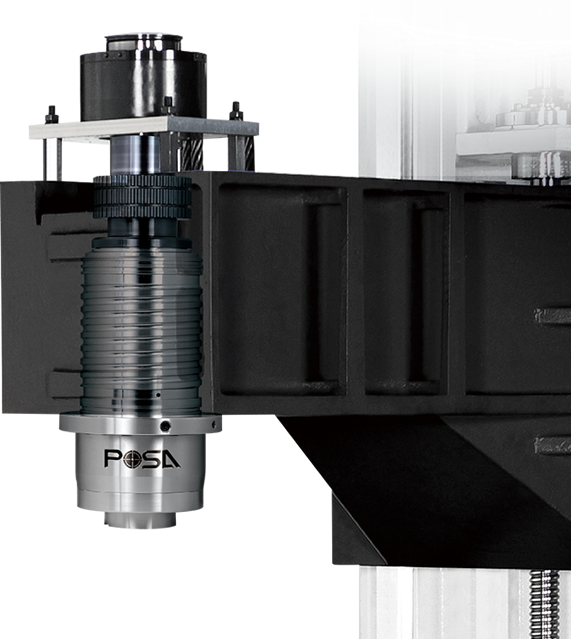

At the forefront of this specialized industry are elite spindle manufacturers like POSA Machinery, who are redefining what performance and durability look like in industrial machining environments.

Image credit: posa-spindle.com

The Spindle is the core of the Machine.

Every CNC machine is as good as the spindle it is mounted on. Think of the spindle as the heart of the CNC lathe, or machining center it powers the cutting tools with extreme accuracy in stability, stability, and torque. Misaligned or poorly-made spindles can lead to faulty components, but they may also harm the machine. This will decrease the longevity of the tool and interrupt the production process.

This is where the precision spindle technology can make all the difference. As opposed to the standard parts which are mass-produced and assembled on the fly precision spindles are precisely developed, tested, and calibrated to work in extreme conditions and on the highest demand.

POSA”Por More Than a Spindle Manufacture

While many spindle manufacturers claim to provide high precision but few have the wealth of the experience and expertise that POSA Machinery has developed over time. POSA’s spindles are known for their strict in-house quality standards and rigorous testing methods. They also design solutions based on performance to meet the diverse demands of the modern workplace.

POSA spindles can be found in a variety of machines, from vertical and horizontal machining centres to grinding tools. Every spindle goes through a rigorous R&D process that focuses not only on the functionality of the spindle, but on its durability and thermal stability.

The Evolution of the CNC Lathe Spindle

Recent years have seen a remarkable amount of innovation with the CNC spindle. Spindles are no longer just rotating axes. They now include sensors as well as cooling mechanisms and intelligent balancing mechanisms. POSA CNC spindles offer an excellent illustration. They blend speedy capabilities and high torque with precision and rigidity, permitting machinists use both delicate materials and metals. With their advanced ceramic bearings and quality construction, these spindles ensure tight tolerances over extended runs. This dependable design results in higher quality parts and less downtime.

Customized Machining Spindles for Machining that Meet the needs of the market.

It is impossible to locate a machining machine that will work for everyone, especially in the fields of aerospace, automotive, and & mould manufacturing. POSA knows that every application requires specific specifications. Whatever the spindle’s speed or load capacity, or environmental protection, POSA can meet them. This is the reason POSA provides customized spindle designs based on the requirements of each customer. POSA can provide the technical support and flexibility that modern manufacturing companies demand, whether it is developing a vertical milling machine or integrating a higher-frequency spindle into a compact machine.

More than Machines A Commitment to Craftsmanship

The POSA philosophy is what separates it from other spindles. The company is dedicated to combining innovation with craftsmanship. Their engineers listen to their customers’ concerns and adapt their products to meet changing market needs. In a world where machine uptime as well as repeatability are essential to the success of a line selecting the best spindle partner is vital.

Final Thoughts

The future of manufacturing doesn’t just depend on higher-speed machines. It is dependent on smarter, more robust components. POSA Machinery is an excellent illustration of the outcomes that can be achieved by spindle manufacturers that blend technical knowledge with a commitment to customer service. The right spindle could transform your idea. This is true whether it’s a high performance CNC lathe spindle that is built to last for a long time or a powerful spindle specifically designed for machining or a highly precise precision spindle.