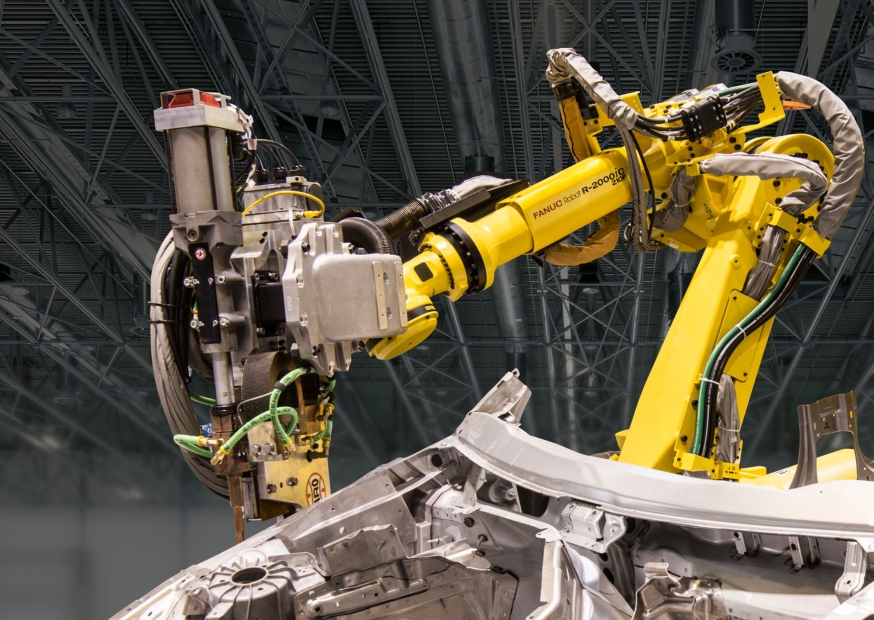

Robotic arms, at heart of modern manufacturing and production have changed the norms in a manner previously thought to be impossible to imagine. They combine precision, safety and efficiency. Robots are amazing mechanical devices which have become indispensable in many industries around the world. They were developed to lower operating costs and keep high standards of quality. The incorporation of robotic arms into the production lines allows companies to not just cut costs, but also enhance workplace safety and productivity. We’ll explore how these innovative machines can transform the way that industrial processes operate.

Image credit: automatedsolutions.com.au

Cost efficiency is the main reason for robot arms’ widespread use. Factories face relentless pressure to reduce manufacturing errors, cut down on the amount of waste and reduce the risk of workplace accidents. Robotic arms were designed to combat these challenges. Robots help avoid costly mistakes and decrease the amount of raw materials, by performing repetitive tasks much more precisely than human beings. For instance, in high-volume industries such as automotive manufacturing, robot arms perform precise welding and part placement, ensuring flawless assembly every time. This precision results in significant savings since fewer imperfections will mean less rework, wasted and work.

Safety is another important aspect of the robotic arm revolution. Numerous manufacturing tasks, like handling dangerous materials or using machines that are heavy can pose dangers to human workers. Robot arms enable companies to remove their employees from dangerous working environments and minimize injuries in the workplace. Robot arms, created as a kinematic chain of flexible joints, mimics functionality of a human arm but operates without the risk of physical harm. Equipped with programmable end effects basically robotic hands, These machines are able to perform tasks like grabbing, spinning or welding in environments that would be unsafe for humans.

The versatility of robotic arms makes them a game-changer across diverse industries. Robot arms can be adapted to different tasks. From assembly for automobiles to electronic production. They can carry out complex tasks with unparalleled precision, like painting and tending of machines. In warehousing and storage, robotic arms have revolutionized palletizing, making it easier to load items onto pallets using precision and speed. Automation not only increases efficiency but also assures reliability, as robot arms are able to work for hours without fatigue.

Cobots are the latest breed of robots that can work alongside humans. Cobots that have robotic arms, unlike industrial robots which are isolated in cells, are designed to interact with human beings safely and smoothly. In a factory environment the robotic arm of a cobot could be able to handle large lifting tasks or repetitive tasks, freeing human workers to focus on more challenging tasks. This collaboration enhances productivity and ensures a safe work area, since cobots are programmed to stop or alter their actions if a person is in the vicinity.

The effect of robotic arms extends beyond safety and efficiency to the very foundations of modern manufacturing. Their capability to do tasks like welding or assembly, as well as material handling with high accuracy has helped them become indispensable in high-stakes industries. For instance, in manufacturing of automobiles, a robot arm is able to rotate and move components during assembly, ensuring an exact alignment with no human intervention. In the electronics industry, robots are used to manipulate fragile components, which minimizes the risk of damage and enhances the quality of output.

As industries continue to develop with the advancement of technology, the need for robotic arms will only grow. Because they are able to cut costs, improve safety, and adapt for different tasks they will become the foundations of future manufacturing. By combining cutting-edge technology with human creativity, robot arms are not just tools. They are partners in development, accelerating innovation and changing our way of building our world.